Projects

- Installing 54″ LED Light Bar

Project Status

- Completed

Time Spent

- 5 Hours

Steps Taken

- Cut 2020 aluminum extrusion with miter saw to 58″ to place on top of existing 80/20 extrusion that is part of Flatline roof rack

- Cut three (3) 1.75″ aluminum mounts with miter saw for connecting 2020 extrusion to 80/20 extrusion

- Drill two holes in each aluminum mount 1″ apart for mounting to extrusion

- Mount extrusion together with aluminum mounts

- 80/20 mount: 1/4-20 bolts, lock washer, flat washer

- 2020 mount: M5 bolts

- Mount LED light bar with 1/4-20 bolts and flat washer to 2020 extrusion

- Thread Locker was used on all bolts

Materials Used

- Keep in mind that prices frequently fluctuate.

- It’s common for products to be delisted on Amazon. If you find a delisted product, please Email Me at steve@campervanfreedom.com and I will fix it.

Tools Used

Notes

- I placed a beam of the 2020 aluminum extrusion on top of the Flatline Roof Rack 80/20 extrusion to light the LED light bar up high enough so it could be angled down towards the ground.

- I used Thread Locker on all bolts to avoid unscrewing over time due to the vibration of the van on the road.

- The T Nuts for the 80/20 extrusion could not be dropped in, and instead had to be slid in at a wide opening on one side of the extrusion. Not realizing his, I had to undo the bolts I had previously tightened in order to slide in another T Nut. However, once the T Nut was slid in, it was easy to bolt into.

- The T Nuts for the 2020 extrusion can be dropped in, but they were more difficult to screw the bolt into because they would move and spin around in the channel. I had to use the thin bars of the allen wrench to fish the T Nuts around in the channel and position correctly, which was time consuming.

Pictures

Short Video

Plans For Tomorrow

- Begin installation of solar panels and roof vent fan

Long-Form Article

Installing a 54″ LED Light Bar on a Camper Van

Enhancing the High Roof Extended Van with a 54″ LED Light Bar: A Project Freedom Adventure

Overview

In my latest endeavor at Project Freedom, I took on the exciting challenge of enhancing my 2023 Ford Transit 250 High Roof Extended van by installing a 54″ LED light bar. This high-quality addition is set to brighten my journey, providing unparalleled safety and visibility as I navigate through the deserts of Phoenix, AZ. This project, a testament to the spirit of adventure and meticulous planning documented on Project Freedom (campervanfreedom.com), highlights the fusion of hands-on effort with high-strength materials and power tools.

Project Status

- Completion: Achieved

- Time Investment: 5 Hours

Execution Steps

- Preparation with Precision:

- Initiated by making angled cuts on a 2020 aluminum extrusion to 58 inches using a sliding compound miter saw. This piece was designed to rest atop an existing piece of the Flatline roof rack, showcasing a blend of high strength and functionality.

- Created three 1.75″ aluminum mounts with the miter saw, establishing connections between the 2020 extrusion and the robust 80/20 framework.

- Assembly with Accuracy:

- Ensured secure attachment by drilling evenly spaced holes in each mount for the LED work light and other components.

- Assembled the framework using 1/4-20 bolts with stainless steel lock and flat washers for the 80/20 mount, and M5 bolts for the 2020 mount, showcasing our commitment to durable and high-quality construction.

- Illuminating Installation:

- Mounted the LED light bar, a beacon of brightness, using 1/4-20 bolts and flat washers on the 2020 extrusion, ensuring a firm bond with medium strength thread locker to withstand the vibrations of the road.

Materials and Tools

- Materials Used: Featured a wide variety of aluminum extrusion, bolts, washers, and thread locker, highlighted by the Nilight – 71017C-A 54″ 312W Curved LED Work Light, a testament to our dedication to high-quality and affordable products.

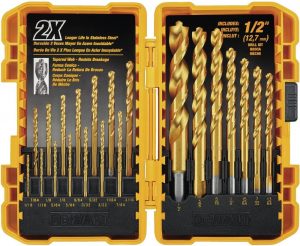

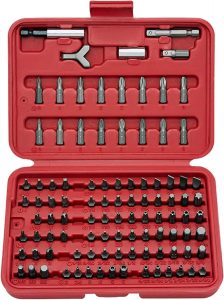

- Tools Employed: Leveraged high-quality power tools and hand tools, including the Dewalt DCD794B 20V MAX ATOMIC COMPACT SERIES Drill Driver and DEWALT 12-Inch Miter Saw, ensuring precision and reliability on job sites.

Insights and Observations

The project underscored the importance of precision and the high bonding strength of thread locker, critical for the project’s long-term durability. It also brought to light the iterative nature of hands-on projects, especially when dealing with a wide range of high-quality materials and tools.

Next Steps

With the LED work lights now casting a wide and bright path ahead, the next adventure involves the installation of solar panels and a roof vent fan, further equipping the van for off-grid living. This progression stands as a testament to Project Freedom’s commitment to exploring new horizons with affordable, high-quality solutions and exceptional customer service.

Stay tuned to Project Freedom for more updates on this journey, as we continue to transform a high roof extended van into a beacon of adventure and freedom on the open road.